Kencana will remain intact to its business principles : Discipline, Reliability and Honesty, which will continue to be the working basis of Kencana. Operate with transparency, adhere to industry regulations, and uphold ethical practices in all business dealings to build trust with clients and partners. Prioritize customer satisfaction by offering tailored solutions, timely delivery, and responsive communication throughout the project lifecycle.

We have been developing parts and products to support growing industries in Indonesia e.g. various plastic based passive hardware for fiber optic in telecommunication industry, and high standard motorcycle helmet for automotive industry. Our goal is to achieve customer satisfaction and become solution partner.

We are ready to develop good relationship and support in producing any kind of plastic parts/products, with our competence and wide experience in mould making and mould repairing. We are ready to supply various kinds of parts or high precision products in accordance with the customer specification at the most competitive price with excellent services and just in time delivery.

We Stand as the Foremost Global Industrial Factory

PT. Kencana as one of the local company with more than 20 Years of experience in plastic injection industry since 2003. We continously adapt to industrial market needs to produce high quality and value added plastic based products to support growing industries in Indonesia.

Production Facilities

We are supported with eight unit of fully computerized Plastic Injection Machines which is completed with an auto loader and unscrewing device. Machines also equipped by auto lubricating system, with various capacities from 60 tones up to 450 tones of clamping force.

We are also supported by two electric chain hoist to support mould mobilization, Mould rack, Chiller and Cooling Tower to maintain the machine temperature, Mould Temperature Control (MTC), Air Compressor complete with Air Dryer, Mixer Machine, Crusher Machine, and three vehicle units for products distribution.

Product

Optical Distribution Point (ODP) with Solid Splitter

Preconnectorized KSO

Marzano Helmet type Prime

Marzano Helmet type Retro Kids

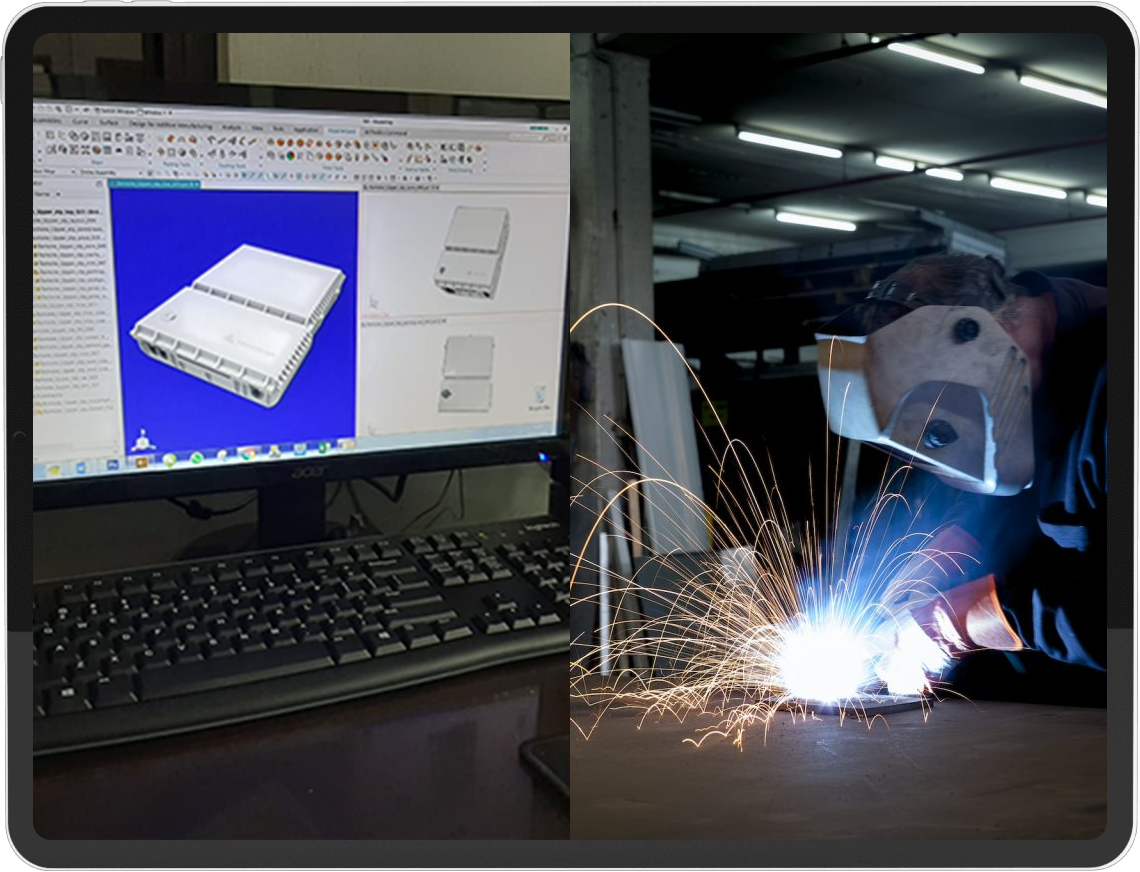

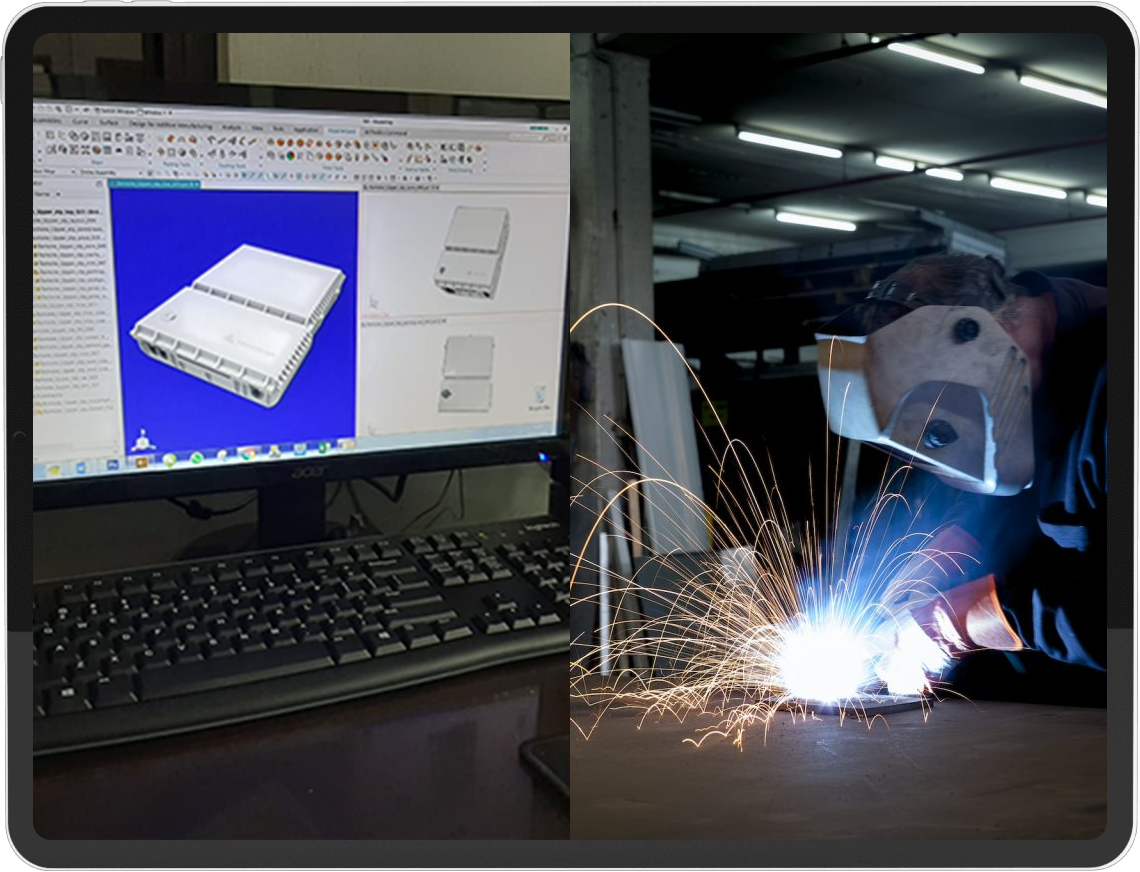

Engineering design

We have been developing technological capabilities in designing mould for plastic products and in designing the high precision product.

The development supported by Computer Aided Design (CAD) and Computer Aided Manufacturer (CAM) as well as other related software.

Workshop

We have experience in integrating our engineering capabilities with our complete workshop facilities in enhancing the effectiveness of repairing and maintaining the mould. These capabilities will optimize of manufacturing process. Our main workshop facilities are CNC Milling, EDM, Wire Cut, Universal Milling, Surface Grinding, Profile Grinding and Turning.

Quality Assurance

Our qualified and experienced staff in Quality Control division with planned and systematic production processes, are ready to assure that the part or product are fit for purpose, right first time and conform with customer quality requirement.

We are currently under continuous improvements, as we have maintain International Quality Management System ISO 9001:2015 to fulfill the customer standard qualification.

Build Quality

Technology

Sustainability

Our Partners